Product Classification

HMDS vacuum oven

Internal dimensions: W450*D450*H450

Product model: AMST-HMDS-090

hiddenValue

- Description

-

No HMDS pretreatment system:

▲Product Introduction:

Necessity of HMDS pretreatment system. In the semiconductor production process, photolithography is an important process link for integrated circuit pattern transfer. The quality of glue coating directly affects the quality of photolithography, and the glue coating process is even more important. In the photolithography glue coating process, most photoresists are hydrophobic, while the hydroxyl groups and residual water molecules on the surface of the silicon wafer are hydrophilic, which causes poor adhesion between the photoresist and the silicon wafer, especially for positive photoresists. During development, the developer will invade the connection between the photoresist and the silicon wafer, which is easy to cause drifting stripes, floating glue, etc., leading to the failure of photolithography pattern transfer. At the same time, wet etching is prone to lateral corrosion. The thickener HMDS (hexamethyldisilazane) can improve this situation well. After HMDS is applied to the surface of the silicon wafer, it can react to form a compound with siloxane as the main body by heating in an oven. It successfully changes the surface of the silicon wafer from hydrophilic to hydrophobic, and its hydrophobic group can be well combined with the photoresist, playing the role of a coupling agent.

The HMDS pretreatment vacuum system can evenly coat a layer of HMDS on the surface of silicon wafers and substrates through parameter control of the vacuum, baking, nitrogen filling, cleaning, HMDS liquid addition and other procedures in the pretreatment process in the box, thereby reducing the contact angle of the silicon wafer after HMDS treatment, reducing the amount of photoresist used, and improving the adhesion between the photoresist and the silicon wafer.

▲Functional features:

1. Control interface: Japan Mitsubishi PLC + 7-inch touch screen control system, programmed operation, temperature system, vacuum system, nitrogen filling system, HMDS injection system.

2. Control module: The control module is the core module of this system. Its function is to control the action and timing of each module and complete the entire process.

3. Liner material: The entire system is made of high-quality medical-grade 316L stainless steel, dust-free material, suitable for the purification environment of a hundred-level photolithography room.

4. Sealing device: The sealing strip is made of high-temperature silicone, which is heat-resistant and non-deformable. The door and the box are connected and sealed to enhance the sealing effect.

5. Heating device: The heater uses SUS304# covered dust-free SHEATHED HEATER with a long life and no pollution. It is adjusted and controlled according to the use temperature to save energy.

6. Heating method: A contactless SCR solid-state relay is used to control the output power of the heating tube in each temperature zone. When it is close to a constant temperature, the heating current becomes smaller to keep it at a constant temperature.

7. Bottom structure: universal mobile Foma integrated load-bearing casters, fixed position can drop the support feet, easy to move and fix

8. Visible window: tempered, bulletproof double-layer glass observation window is used to observe the experimental conditions of items in the studio.

9. The temperature sensor uses imported PT100 platinum resistor, accuracy ±0.5%, sensitive response, high temperature resistance.

10. Vacuum system: composed of double rotary vane vacuum pump, vacuum components, pressure measurement, etc., the main function is to replace gas and extract residual HMDS vapor.

11. Nitrogen filling system: the function is to gradually dilute the air or liquid vapor with nitrogen during the replacement process, so as to finally replace the atmosphere of air or liquid vapor. The nitrogen flow rate and filling time can be controlled.

12. HDMS liquid injection system, HMDS gas closed automatic absorption and addition design, equipped with stainless steel liquid pipeline, so that the vacuum box has good sealing.

13. Protection system: phase sequence protection, leakage protection, overload protection, control circuit, overtemperature protection, pressure overload protection, emergency stop switch, working status indicator light.▲3. HMDS (hexamethyldisilazane) process:

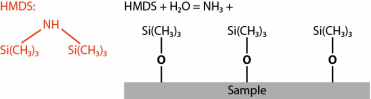

*HMDS reacts with the oxide surface to form as shown, but also leaves free bonds to react with the photoresist and improve adhesion.

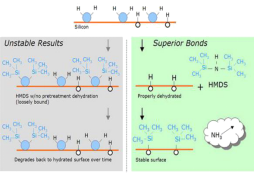

* Steam initiation of HMDS with dehydration baking (is process): As the wafer surface becomes more hydrophobic, HMDS will bind and hydrate the molecular water on the wafer surface and increase the liquid contact angle. An initial high temperature bake and dehydration process are also required to allow the substrate to be uniformly and stably steam initiated, and this complete dehydration process is required before HMDS application to produce a stable surface.

▲Comparative study of the main performance of HMDS

The reduction of critical feature sizes in the extremely small submicron range is increasingly rare, requiring excellent photolithography processes during manufacturing. The adhesion of the photoresist is always very important because it directly affects the control of the critical dimensions of the etched image. Therefore, the HMDS process has also been implemented in various coater tracks with varying degrees of success.

▲Process flow:

The working process and mechanism of HMDS oven First, set the working temperature of the oven. The typical pretreatment procedure is: turn on the vacuum pump to evacuate, and when the vacuum degree in the chamber reaches 5000Pa, start to fill with nitrogen. After filling to 90000Pa, evacuate again and fill with nitrogen to purge the chamber back and forth. After reaching the set purge times, start evacuating to 2000Pa again, and fill with HMDS gas blown out by nitrogen. After reaching the set time, stop filling with HMDS solution and enter the holding stage to allow the silicon wafer to fully react with HMDS. When the set holding time is reached, start evacuating again. Fill with nitrogen to purge the HMDS residue back and forth. After reaching the set purge times, the operation process is completed.

▲Water drop angle and process parameters:

HMDS can increase the adhesion between photoresists, but too large a contact angle will lead to an increase in the amount of photoresist used. Properly reducing the contact angle can effectively reduce the amount of photoresist used and save costs. The following figure shows the relationship between a typical treatment process and a water drop angle:

Fill vacuum/pa

Temperature/℃

HMDs charging time/S

Hold time/S

Water drop angle/°

Glue volume/cc

2000

150

120

120

65.4

2.7

2000

140

80

110

62.1

2.3

2000

150

120

150

71.6

3.4

▲Model Specifications

model

AMST-HMDS-090

AMST-HMDS-210

Supply voltage

220V/50HZ

380V/50HZ

Temperature control range

RT+10℃-250℃

Temperature resolution

0.1℃

Temperature fluctuation

≤±0.5℃

Vacuum

≤133Pa

Workshop size (mm)

W450*D450*H450

W560*D600*H600

Dimensions (mm)

W850*D700*H1490

W960*D850*H1620

Number of layers

2 pieces

3 pieces

power

3KW

4.5KW

key word:Double door dual control oven

Previous:

Product Inquiry

Please leave your phone, our professionals will contact you as soon as possible